Research and development, production, and sales of intelligent equipment for automatic welding machine.

Cost-Effective Welding with Spot Projection Machines: A Detailed Analysis

Improving the Draft: Enhancing Clarity and Readability

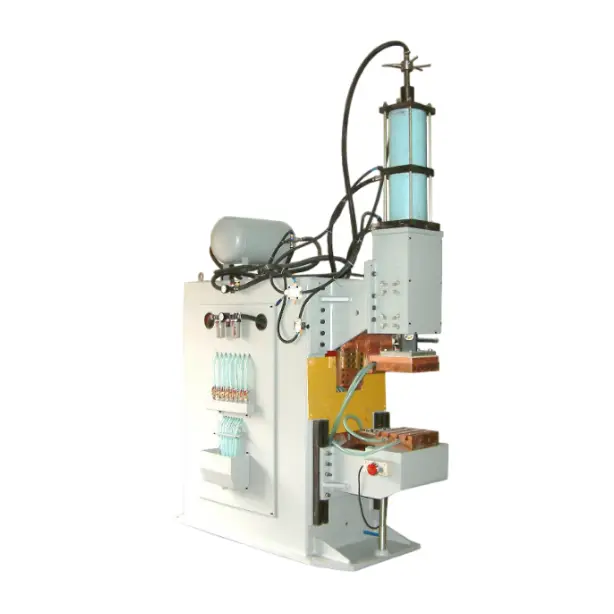

Spot projection welding machines utilize a high-velocity arc to project onto the base metal and filler metal, creating a precise weld pool. The key components include a welding head with a projecting electrode, a projector to focus the arc, and a support structure. This precise method ensures that only the intended area is weldable, reducing the need for extensive material and setup.

Key Components and Process

- Projecting Electrode: The machine uses a projecting electrode to focus the arc.

- Focusing the Arc: By focusing the arc, the machine ensures precision and control over the weld zone.

- Weld Pool Formation: The projected arc melts and fuses the base and filler metals, creating a high-quality weld.

Precision and Control

The technology allows for precise control over the weld, making it ideal for small and intricate parts. This precision minimizes material waste and produces high-quality welds, essential for industries requiring reliability and performance.

Applications and Where Spot Projection Welding Shines

Spot projection welding machines find practical applications in various industries, each benefiting from the technology in unique ways.

Automotive Industry

In the automotive sector, spot projection welding is used for undercarriage parts. For example, it can weld small and intricate components like suspension pieces, reducing production time and material waste.

Electronics Industry

In electronics, the method is utilized for assembling printed circuit boards, ensuring reliable and long-lasting connections. This precision is critical in electronics where even small defects can compromise functionality.

Energy Industry

Energy companies use spot projection welding for transformer repairs. The technology enables the welding of intricate and delicate components, ensuring durability and reliability in critical applications.

The Advantages: A Comprehensive Overview

Spot projection welding machines offer several advantages, making them a highly viable solution in modern manufacturing.

Precision and Quality

- Minimal Material Waste: The focused arc ensures only the intended area is weldable, reducing material usage.

- High-Quality Welds: The precision of the process results in superior weld quality, crucial for maintaining reliability and performance.

Cost-Effectiveness

- Reduced Labor Costs: Automation increases efficiency, allowing skilled workers to focus on more value-added tasks.

- Lower Energy Consumption: The energy-efficient design reduces operational costs and environmental impact.

Challenges and Solutions: Overcoming the Obstacles

While spot projection welding machines offer numerous benefits, some challenges must be addressed.

Setup and Integration

- Complex Integration: The initial setup and integration with existing production lines can be complex. However, working closely with suppliers can ensure a smooth transition.

- Employee Training: Operators need specialized training to master the technology. Comprehensive training programs can help staff become proficient.

Future Prospects: The Road Ahead

The future of spot projection welding holds significant promise with emerging trends and technological advancements.

Integration of AI and Machine Learning

AI and machine learning can enhance precision and efficiency, potentially automating even more aspects of the welding process.

Additive Manufacturing

Combining spot projection welding with additive manufacturing opens new possibilities for complex and customized components.

A New Era of Welding Efficiency

Spot projection welding machines represent a significant leap forward in welding technology, offering cost savings, precision, and adaptability. By eliminating the need for large filler volumes and reducing material waste, these machines are revolutionizing the way small and intricate parts are produced. As industries continue to embrace this technology, the door is opening to a new era of welding efficiency, where cost-effectiveness and quality go hand in hand.